Cartridge valves are an improvement over sub plate mounted

or conventional valves , where applications involving flow , pressure

capability , reliability of operation and cost are concerned.

These valves offer a design alternative over conventional

spool type valves . These are most often employed in conjunction with spool

valves all integrated into one system.

Slip –In cartridge

valves

These valves are similar to poppet check valves

and are usually inserted into a cavity. These insert consist of Sleeve ,

Poppet , Spring and seals.

This has two main flow ports , denoted by notations “ A “ and “ B “.- In and Out.

Control port is denoted by “ X “ , which consists of a drilled passage with/

without orifice control to Spring chamber denoted by “AP”.

These valves are often designed with respect to area ratios(AAP/ AA - Area of Spring chamber/ Inlet Area) -

depending upon the flow and application - Standard areas being 1:1 , 1.1:1 and 2:1.

Further classified as metering notch – depending upon the

flow characteristics involved.

Hydraulic delay in the system (To close/ open) is introduced by orifice , in order to handle

smooth transition of flows – this is application dependent.

Covers:

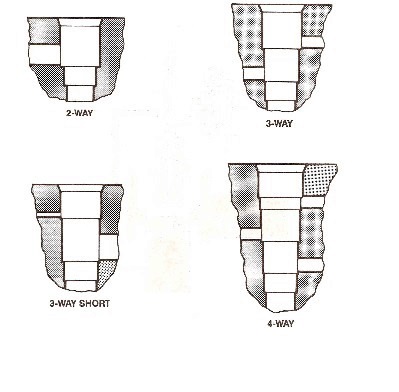

These are classified as

1.Standard cover with a simple control port (with / without orifice)

2.Pilot valve interfaced cover , with Auxiliary ports Z1 and

Z2 connected to other valve pilots to provide operation of more than one

cartridge valves in system.

3. Shuttle cover , which is incorporated with a shuttle

valve – to choose higher pressure of two pilot ports “X” and “ Y “ and direct

operation -spring port “AP”, with Z2 connected to the center port.When solenoid is energized , this drains poppet spring chamber

and fluid can travel either direction by overcoming the spring holding the

poppet closed.

4. Pilot operated check valve cover :

5.Pressure Control Slip in cartridge valves:

Heads can be used in conjunction to achieve various functions , depending upon the application to be used. One such example uses a plot valve to vent a pressure control valve - to operate as pressure control valve and to release immediately with pilot operation.- Known as Spring offset single solenoid direction valve.

The Pressure reducing valve below uses a Pilot valve head, with an adjustable screw and spring poppet.

Cartridge valves with Notations

1. Non - pressure compensated flow control :

This control comprises of elements , where in flow is adjusted by a throttle and is not guided by changes in flow - only by pressure drop.Hence no compensation for any changes in flow - only change in pressure .

2.Pressure compensated bypass type flow control: Flow rate is adjusted by keeping a constant differential pressure across throttle , regardless of load pressure.

A pressure compensated non adjusted bypass flow type is shown below.

3. Pressure compensated restrictor type flow control: A pressure reducing valve insert with a standard cover acts as a compensator when connected in series with a metering insert 1:2 , where pressure is compensated by a load sensing line.

Pressure compensated restrictor type with screw in cartridges is shown as below.

A pressure compensated bypass type with screw in cartridges is shown below:

A typical load application of pressure compensated valves is as shown below.

Differential pressure sensing valve elements are used in conjunction applications in pressure systems and cannot perform a complete valve function as cartridge inserts.These respond to differential pressure sensed at other inserts , hence the logic is an on / off system output type. and are used with pilot elements.

The basic notations are shown as below:

The valve inserts are shown as below:

No comments:

Post a Comment