1.Belt Nomenclature

All A,B,C,D,E,AX,BX belts list the inside

circumference measurement after the letter of the v belt part number. Example:

A88 has a 88" inner circumference, then you add 2 inches for the A Section

(Listed below) to obtain the outer circumference. If you measure the outer

circumference, then you would subtract the number of inches based on the

section you have (Listed below) to obtain the v belt number. This is also the

same for the banded belts. Measure each individual band for banded belts to

obtain the correct width.

Examples of how belt numbers are coded per

section:

A Section= Add 2" to belt number (Example

A88 = 90" Outside Circumference)

B Section= Add 3" to belt number (Example

B88 = 91" Outside Circumference)

C Section= Add 4" to belt number (Example

C88 = 92" Outside Circumference)

D Section= Add 5" to belt number (Example

D105 = 110" Outside Circumference)

E Section= Add 6" to belt number (Example

E144 = 150" Outside Circumference)

AX Section= Add 2" to belt number (Example

AX60 = 62" Outside Circumference)

BX Section= Add 3" to belt number (Example

BX50 = 53" Outside Circumference)

How fractional & wedge belt numbers are coded

All sections 3L,3V,5V,8V,3VX,5VX belts have the

outside circumference after the number and letter(s). Example: Belt # 3V600 has

a 60" outside circumference. Inside circumference are not measured for

these sections. This is also for the banded belts. Measure each individual band

for banded belts to obtain the correct width.

Examples of how belt numbers are coded per

section:

3L Section= (Example 3L450 = 45" Outside

Circumference)

3V Section= (Example 3V800 = 80" Outside

Circumference)

5V Section= (Example 5V1180 = 118" Outside

Circumference)

8V Section= (Example 8V2120 = 212" Outside

Circumference)

3VX Section= (Example 3VX520 = 52" Outside

Circumference)

5VX Section= (Example 5VX810 = 81" Outside

Circumference)

Measuring K,L,M Micro Rib Belts:

Width's

K Section= 0.140" X's the number of ribs

L Section= 0.185" X's the number of ribs

M Section= 0.370" X's the number of ribs

All sections K,L,M belts will have the outside

circumference in front of the letter. The rib count will be the number after

the letter.

Outside Circumference & Rib Count per

section:

K Section= (Example 845K8 = 84.5" Outside

Circumference and 8 Ribs)

L Section= (Example 540L10 = 54" Outside

Circumference and 10 Ribs)

M Section= (Example 940M6 = 94" Outside

Circumference and 6 Ribs

Keep in mind belts do stretch and unfortunately there is no specific given value for how much a belt stretches.

2.V-Belt Defects

When inspecting a V-belt, look at these

areas for signs of uncommon wear:

- Top surface

- Top corners

- Belt sidewalls

- Bottom corners

- Bottom surface

- Undercord cracking

- Sidewall burning or hardening

- Belt surface hard or stiff

- Belt surface flaking, sticky

or swollen

Top surface wear might be the

result of the belt rubbing against the guard, or by a fail of the idler.

Control these areas, and fix or change the guard and/or idler to correct the

anomaly.

Wear on the top corners of the belt could be

the sing that the belt is smaller for the groove in the sheaves. Changing the

belt for the right sheave will fix the problem.

Severe wear along the belt sidewalls may be due to several factors. The belt may be

slipping due to a bad tension. In that case, increase tension until the

slipping stops. Another possible problem is sheave misalignment, which needs to

realigning the drive. In this case, change the sheaves. Or the belt could simply

be the inappropriate size and needs to be change with the right size.

Wear on the bottom corners of the belt may be

causes by worn sheaves or an improper fit between belt and sheave. Control the

sheaves for wear and change them if needed, or find the right belt/sheave

match.

Bottom surface belt wear may be due to fragments in the sheaves, sheave

wear, or the belt bottoming out against the sheave grooves. Bottoming out is

due to an improper match between belt and sheave, and can be fixed by choosing

the proper match. If the sheaves are worn, change them, and if fragments has

gotten into the sheaves, clean them.

Undercord cracking could be cause by a plenty of factors.

Environmental conditions (severe heat or cold) or a bad storage could be

responsible. Solutions involve checking the belt drive environment and

following the right storage and handling protocol.

Another cause could be belt slip, fixed

by re-tensioning the belt to the manufacturer’s suggestions. A sheave that is

smaller for the belt section, causing the belt to wrap too tightly around the

sheave, could crack the undercord. Changing the small sheave with a larger one

may fix the problem. Likewise, a backside idler with a small diameter may be

the problem, corrected by increasing the size of the backside idler.

Sidewall burning or hardening may be due to worn sheaves or shaft movement

or under-designed drive. A slipping belt must be re-tensioned to the manufacturer’s

protocol.

A worn sheave must be changed. If the

drive is under-designed, ask the manufacturer’s recommendations to redesign it.

Shaft movement may be due to a changes in the center distance between the

sheaves, and must be controlled and adapted.

If the belt surface is hard or stiff, it

may be cause by a severe hot environment or to belt slip. Fix the problem by

given more ventilation to the drive or adapting belt tension.

A belt surface that is swollen ,flaking

or sticky could have been contaminated

by oil or chemicals. Eliminate the contamination and its source, and never

apply belt dressing.

Banded (joined) V-belt problems

Banded V-belts (multiple belts with a

common cover that serves as a tie-band) could show signs that point to a drive

complication. The following symptoms call for investigation:

- Tie-band separation

- Top of tie-band frayed, worn or damaged

- Banded belt comes off sheaves repeatedly

- One or more belt ribs run outside the sheave

Tie-band separation may be the cause of a bad groove spacing.

Control the sheaves to be sure that they have been manufactured to industry

requirement. Another cause may be worn or wrong sheaves, which needs changing

the sheaves. Also control to see if the sheaves are misaligned, which may force

a separation of the tie-bands. Realign the drive to fix the problem.

If the top of the tie-band is damaged,

worn or frayed, , decide if the belt is interfering with the guard and adapt the

guard as desired. Another possible cause is worn or wrong sheaves. Change the

sheaves to resolve the problem. Debris in the sheaves could also damage the

tie-band, so clean the sheaves if required.

When a banded belt jumps off the

sheaves, two cases are possible. Either items has penetrated into the sheaves,

or they are misaligned. Align the drive to fix any misalignment problems. If

item is a problem cause by the type of use, clean out the sheaves and use

single belts rather than a banded belt.

A belt that has ribs running outside

the sheaves could be under-tensioned. Control the manufacturer’s protocol and

re-tension the belt. Another possible cause is sheave misalignment. Realign the

drive to fix it.

Problems Common to Single and Multiple V-Belts

Two problems current to both single

V-belts and Poly V-belts include belts coming off the sheave or turning over,

and belts stretching beyond the available take-up.

There are a plenty of probable causes

and remedial actions for single or Poly V-belts turning over or coming off the

sheave

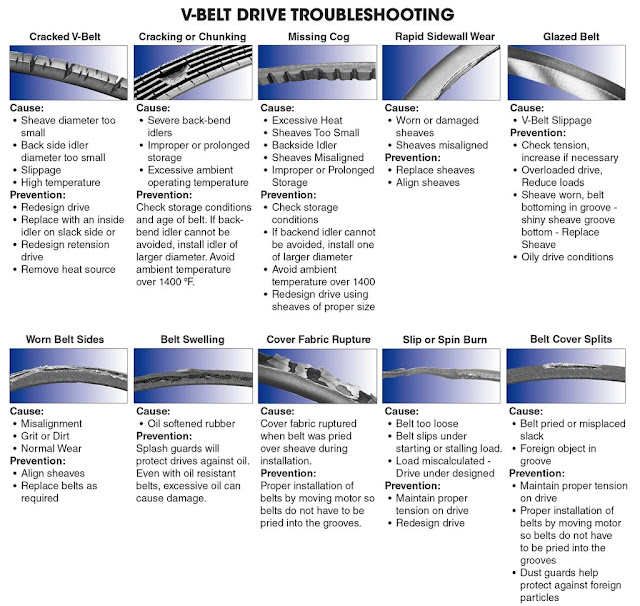

A simplifies trouble shooting for single v belts can be explained as under:

Nice post. I found Industrial V Belts in India for modern use at a reasonable cost. They have an incredible stun engrossing limit and drive consistency. Love It.

ReplyDeleteThank you for such a great post, a valve is a device that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Poly V Belts visit us.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteHi, I have come across your blog through search and found that it is really great with lots of informative stuff about poly v belts and their poly v belt manufacturers in india. I have bookmarked your blog for future references. Thanks for sharing this wonderful information.

ReplyDeleteBest SS Cable Tie Manufacturers deliver premium stainless steel ties with corrosion resistance, high tensile strength, and customizable sizes for industrial, marine, and automotive applications.

ReplyDeleteLipo Technology Private Limited is a trusted name among leading SS Allen Bolt Manufacturers , offering premium-grade stainless steel fasteners designed for strength, durability, and precision. Our SS Allen bolts are widely used across construction, engineering, and industrial applications, ensuring superior performance and resistance to corrosion. With advanced manufacturing facilities and strict quality standards, we deliver reliable fastening solutions tailored to diverse needs. For more details, contact us at +91 9722266550.

ReplyDelete