All dimensions in MM

CHAIN

RULES OF THUMB :

ESTIMATED SWL OF

CHAIN : (DIAMETER

IN MM - SQUARED) x GRADE x 0.4

(EXAMPLE : WLL of

grade 80 high tensile chain 10 mm = 10 x 10 x 80 x 0.4=

3,200 kg WLL.)

MAXIMUM PERMISSIBLE WEAR

INCLUDING PITTING WEAR : 10% REDUCTION IN DIAMETER OF CROSS SECTION AT ANY POINT

WEAR POINTS IN A CHAIN

:

Links will wear at the

link ends from metal wear down.

Links will wear on the

outer sides of the link from being dragged

SMALLEST CHAIN DIAMETER

FOR LIFTING:

GRADE 30 (BASIC GRADE)

: 8.0 MM

HT GRADE 80 CHAIN

: 5.5 MM

MAXIMUM WORKING

TEMPERATURE

GRADE 30 (BASIC GRADE)

: 260 DEGREES CENT

HT GRADE 80 CHAIN

: 400 DEGREES

CENT

IF TEMPERATURE EXCEEDS

260 DEGREES CENT- WLL OF CHAIN GETS DRASTICALLY REDUCED.

MARKINGS INDICATE- IF

THE CHAIN IS FOR LIFTING AND ALSO THE GRADE- MOST CHAINS ARE MARKED AT EVERY 20

TH LINK OR A DISTANCE OF 1 METER.

IF CHAIN HAS NO WLL TAG :

*DISCARD THE SAME FROM

SERVICE TILL CHECKED PROPERLY --IF IT HAS NO TAG AND GRADE MARKING

*CHECK GRADE MARKINGS AND

USE ACCORDINGLY TILL NEW TAG IS MARKED

*IF UNSURE ABOUT MARKINGS

, TREAT IT AS GRADE 30 CHAIN FOR USE- PROVIDED CONDITION IS GOOD UNTIL

PROPERLY CHECKED .

DEFECTS IN CHAIN MAKING

IT UNFIT FOR USE:

1.Twisted, kinked,

knotted.

2.Stretched, locked or

does not move freely.

3.Gouged, cut or crushed

more than 10% of the link's original diameter.

4.Pitting more than 10%

wear in the diameter of the link.

5.Exposed to excessive

heat.

CHAIL LINK , RINGS , BOW PIECES FOR SWIVELS

Swivels are to be fitted with plain bearings or with ball or roller thrust bearings

|

Minimum tensile

strength

of material, |

|

Value of c

|

|

|

in N/mm2

|

Links

|

|

Rings

|

|

|

|

|

|

|

430

|

0,0053

|

|

0,0116

|

|

540

|

0,0071

|

|

0,0155

|

Swivels are to be fitted with plain bearings or with ball or roller thrust bearings

Dimensions of bow pieces for swivels(in MM)

|

Safe working

load,

in tonnes

|

a b d1 d2

|

e

|

|

1,0

|

37 64 13 20

|

20

|

|

1,6

|

46 80 16 25

|

25

|

|

2,0

|

53 92 18 25

|

29

|

|

2,5

|

60 104 21 30

|

32

|

|

3,2

|

67 116 23 30

|

36

|

|

4,0

|

74 128 26 35

|

40

|

|

5,0

|

83 144 29 40

|

45

|

|

6,3

|

92 160 32 40

|

50

|

|

8,0

|

104 180 36 45

|

56

|

|

10,0

|

117 204 41 55

|

64

|

|

12,5

|

131 228 46 60

|

71

|

HOOKS

The safe working load of a hook is the maximum load that the hook is certified to lift in service.

-Hooks may be of the ‘C’ or Liverpool type or of the double armed Ramshorn type, as indicated

- ‘C’ type hooks are not to be used for safe working loads exceeding 25 t.

-Hooks may be of killed mild steel or higher tensile steel. After forging, mild steel hooks are to be normalised and higher tensile steel hooks subjected to a suitable heat treatment.

‘C’ type hooks are to be so designed as to reduce as far as possible the risk of the hook catching on an obstruction when hoisting and also the risk of the displacement of the load.

**Where the hook is not manufactured in accordance with a recognised standard, the safe working load may be taken as:

SWL = ck (H – 0,1D)2 tonnes

where the dimensions are measured in millimetres

The values of c and k are to be obtained

Values of c for hooks(INTERMEDIATE VALUES OBTAINED BY INTERPOLATION)

in N/mm2 'C' hooks Ramshorn hooks

540 0,0015 0,0021

Values of k for hooks

|

M

|

|

|

|

|

q

|

|

|

|

|

H

|

40°

|

30°

|

25°

|

20°

|

15°

|

10°

|

5°

|

0°

|

|

0,55

|

0,48

|

0,75

|

0,85

|

0,92

|

0,98

|

1,03

|

1,06

|

1,10

|

|

0,65

|

0,82

|

1,01

|

1,08

|

1,12

|

1,16

|

1,20

|

1,23

|

1,27

|

|

0,75

|

1,07

|

1,18

|

1,22

|

1,27

|

1,30

|

1,34

|

1,37

|

1,40

|

|

0,85

|

1,16

|

1,30

|

1,33

|

1,36

|

1,40

|

|

|

|

|

Safe working

load,

in tonnes

|

a

|

b

|

c

|

D

|

H

|

M

|

G

|

|

1,0

|

124

|

78

|

6

|

31

|

26

|

17

|

17

|

|

1,6

|

156

|

98

|

8

|

39

|

33

|

21

|

20

|

|

2,0

|

176

|

110

|

8

|

44

|

37

|

24

|

25

|

|

2,5

|

196

|

123

|

10

|

49

|

41

|

27

|

25

|

|

3,2

|

219

|

138

|

12

|

55

|

46

|

30

|

30

|

|

4,0

|

247

|

156

|

12

|

62

|

52

|

34

|

30

|

|

5,0

|

279

|

176

|

14

|

70

|

59

|

38

|

35

|

|

6,3

|

311

|

196

|

16

|

78

|

66

|

43

|

40

|

|

8,0

|

351

|

221

|

18

|

88

|

74

|

48

|

45

|

|

10,0

|

391

|

246

|

20

|

98

|

82

|

54

|

50

|

|

12,5

|

439

|

276

|

22

|

110

|

92

|

60

|

55

|

|

16,0

|

495

|

311

|

24

|

124

|

104

|

68

|

60

|

|

20,0

|

555

|

349

|

28

|

139

|

117

|

76

|

70

|

|

25,0

|

622

|

392

|

32

|

156

|

131

|

86

|

80

|

|

NOTES

|

|

|

|

|

|

|

|

|

1.

All dimensions are given

in millimetres and are illustrated

|

|

|

|

|

|||

|

2. Minimum material tensile strength 540 N/mm2.

|

|

|

|

|

|||

Dimensions

of higher tensile steel Ramshorn hooks

|

Safe working

load,

in tonnes

|

a

|

b

|

c

|

D

|

H

|

M

|

G

|

|

20

|

238

|

457

|

30

|

121

|

113

|

76

|

89

|

|

25

|

267

|

511

|

33

|

133

|

126

|

86

|

102

|

|

32

|

299

|

567

|

37

|

146

|

143

|

97

|

114

|

|

40

|

329

|

616

|

41

|

162

|

155

|

108

|

127

|

|

50

|

365

|

683

|

46

|

178

|

174

|

117

|

140

|

|

63

|

408

|

745

|

51

|

194

|

195

|

132

|

144

|

|

80

|

452

|

813

|

57

|

213

|

216

|

146

|

152

|

|

100

|

498

|

883

|

64

|

229

|

241

|

162

|

165

|

|

NOTES

|

|

|

|

|

|

|

|

|

1.

All dimensions are given

in millimetres and are illustrated

|

|

|

|

|

|||

|

2. Minimum material tensile strength 540 N/mm2.

|

|

|

|

|

|||

Shackles should be inspected for:

(a) Mechanical damage to pin or body;

(b) Correct tensile pin fitted;

(c) Correct pin length; and

(d) Wear.

Mild steel shackles are to be normalised after forging and before tapping and screwing. Higher tensile and alloy steel shackles are to be subjected to a suitable heat treatment.

Safety factor: 6 times SWL = minimum breaking strength

Dimensions of Dee shackles

Safe working

load,

in tonnes

|

a

|

b

|

d1

|

Mild steel

d2

|

d1

|

Higher tensile steel

d2

|

1,0

|

20

|

44

|

13

|

15

|

11

|

12

|

1,6

|

25

|

55

|

17

|

19

|

13

|

15

|

2,0

|

28

|

62

|

19

|

21

|

15

|

17

|

2,5

|

31

|

69

|

21

|

24

|

17

|

19

|

3,2

|

35

|

78

|

24

|

27

|

19

|

21

|

4,0

|

40

|

87

|

26

|

30

|

21

|

23

|

5,0

|

44

|

97

|

29

|

33

|

23

|

26

|

6,3

|

50

|

109

|

33

|

37

|

26

|

29

|

8,0

|

56

|

123

|

37

|

42

|

29

|

33

|

10,0

|

63

|

138

|

41

|

47

|

33

|

37

|

12,5

|

70

|

154

|

46

|

53

|

36

|

42

|

16,0

|

79

|

174

|

52

|

60

|

41

|

47

|

20,0

|

89

|

195

|

59

|

67

|

46

|

52

|

25,0

|

99

|

218

|

65

|

75

|

51

|

59

|

32,0

|

112

|

247

|

74

|

84

|

58

|

66

|

40,0

|

125

|

275

|

83

|

94

|

65

|

74

|

50,0

|

140

|

308

|

92

|

106

|

72

|

83

|

63,0

|

157

|

346

|

104

|

119

|

81

|

93

|

80,0

|

177

|

390

|

117

|

134

|

91

|

105

|

Dimensions of Bow shackles

Safe working

load,

in tonnes

|

a

|

b

|

2r

|

d1

|

Mild steel

d2

|

Higher tensile steel

d1 d2

|

|

1,0

|

20

|

50

|

34

|

14

|

16

|

12

|

13

|

1,6

|

25

|

63

|

43

|

18

|

20

|

15

|

16

|

2,0

|

28

|

70

|

48

|

20

|

22

|

17

|

18

|

2,5

|

31

|

78

|

53

|

23

|

25

|

18

|

20

|

3,2

|

35

|

89

|

60

|

25

|

28

|

21

|

22

|

4,0

|

40

|

99

|

67

|

28

|

31

|

23

|

25

|

5,0

|

44

|

111

|

75

|

32

|

35

|

26

|

28

|

6,3

|

50

|

124

|

84

|

36

|

39

|

29

|

32

|

8,0

|

56

|

140

|

95

|

40

|

44

|

33

|

36

|

10,0

|

63

|

157

|

106

|

45

|

49

|

36

|

40

|

12,5

|

70

|

175

|

119

|

50

|

55

|

41

|

44

|

16,0

|

79

|

198

|

135

|

56

|

62

|

46

|

50

|

20,0

|

89

|

221

|

150

|

63

|

69

|

51

|

56

|

25,0

|

99

|

248

|

168

|

70

|

77

|

57

|

63

|

32,0

|

112

|

280

|

190

|

80

|

87

|

65

|

71

|

40,0

|

125

|

313

|

213

|

89

|

98

|

72

|

79

|

50,0

|

140

|

350

|

248

|

99

|

109

|

81

|

89

|

63,0

|

157

|

394

|

267

|

112

|

123

|

91

|

100

|

80,0

|

177

|

444

|

301

|

126

|

138

|

102

|

112

|

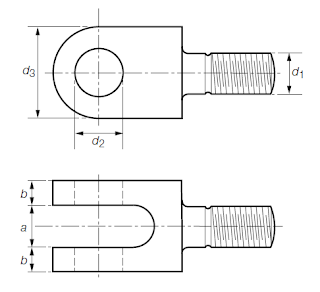

LUGS

Dimensions of lug fittings

Safe working

load,

in tonnes

|

Shank

d1 |

a

|

b

|

d2

|

d3

|

1,0

|

M18

|

19

|

8

|

17

|

35

|

1,6

|

M22

|

23

|

11

|

21

|

45

|

2,0

|

M24

|

26

|

12

|

23

|

50

|

2,5

|

M27

|

29

|

13

|

25

|

55

|

3,2

|

M30

|

32

|

14

|

28

|

60

|

4,0

|

M33

|

35

|

15

|

31

|

65

|

5,0

|

M36

|

39

|

18

|

37

|

75

|

6,3

|

M42

|

45

|

20

|

40

|

85

|

8,0

|

M45

|

49

|

23

|

46

|

95

|

10,0

|

M52

|

58

|

26

|

50

|

110

|

12,5

|

M56

|

64

|

28

|

54

|

120

|

16,0

|

M64

|

70

|

30

|

62

|

130

|

20,0

|

M72 x 6

|

74

|

33

|

70

|

140

|

25,0

|

M76 x 6

|

80

|

35

|

74

|

150

|

32,0

|

M80 x 6

|

90

|

40

|

82

|

170

|

RIGGING SCREWS AND TURNBUCKLES

Rigging screws and turnbuckles should be inspected for:

(a) Thread damage and thread engaged to full length of threaded body;

(b) Deformation; and

(c) Corrosion.

Thread Diameter

(A)

|

Safe Working Load

(SWL) |

Thread Diameter

(A)

|

Safe Working Load

(SWL) |

mm

|

tonnes

|

mm

|

tonnes

|

8

|

0.2

|

39

|

6.0

|

10

|

0.3

|

42

|

7.5

|

12

|

0.5

|

48

|

10.0

|

16

|

0.75

|

56

|

15.0

|

20

|

1.25

|

64

|

20.0

|

22

|

2.0

|

72

|

25.0

|

27

|

3.0

|

76

|

30.0

|

30

|

4.0

|

85

|

40.0

|

33

|

5.0

|

100

|

50.0

|

BULL DOG GRIPS

Size Nominal Diameter

mm

|

Required Number of Wire Rope Grips to

Attain 85% of Rope Minimum Breaking Load

|

Required Tightening Torque to Obtain Required Efficiency

Newton metres

|

5.0

|

3.0

|

2.0

|

6.5

|

3.0

|

3.5

|

8.0

|

4.0

|

6.0

|

10.0

|

4.0

|

9.0

|

13.0

|

4.0

|

33.0

|

16.0

|

4.0

|

49.0

|

19.0

|

4.0

|

68.0

|

22.0

|

5.0

|

107.0

|

26.0

|

5.0

|

147.0

|

30.0

|

6.0

|

212.0

|

34.0

|

6.0

|

296.0

|

40.0

|

6.0

|

363.0

|

Safe working

load,

in tonnes

|

Shank

d1 |

Round

d2

|

d3

|

b

|

g

|

Oval

d4

|

e

|

1,0

|

M18

|

11

|

24

|

48

|

21

|

12

|

14

|

1,6

|

M22

|

14

|

30

|

58

|

26

|

16

|

18

|

2,0

|

M24

|

16

|

34

|

58

|

26

|

16

|

18

|

2,5

|

M27

|

18

|

39

|

72

|

32

|

21

|

23

|

3,2

|

M30

|

20

|

44

|

72

|

32

|

21

|

23

|

4,0

|

M33

|

22

|

48

|

94

|

40

|

26

|

28

|

5,0

|

M36

|

25

|

54

|

94

|

40

|

26

|

28

|

6,3

|

M42

|

27

|

60

|

108

|

45

|

29

|

32

|

8,0

|

M45

|

31

|

68

|

115

|

49

|

32

|

35

|

10,0

|

M52

|

35

|

76

|

125

|

54

|

36

|

39

|

12,5

|

M56

|

39

|

86

|

144

|

60

|

41

|

44

|

16,0

|

M64

|

163

|

66

|

46

|

49

|

||

20,0

|

M72 x 6

|

173

|

72

|

56

|

54

|

||

25,0

|

M76 x 6

|

192

|

80

|

56

|

59

|

||

32,0

|

M80 x 6

|

216

|

90

|

60

|

64

|

||

40,0

|

M90 x 6

|

240

|

100

|

66

|

70

|

||

50,0

|

M100 x 6

|

264

|

110

|

74

|

78

|

||

63,0

|

M110 x 6

|

290

|

120

|

84

|

89

|

||

80,0

|

M120 x 6

|

325

|

135

|

94

|

99

|

||

100,0

|

M130 x 6

|

360

|

150

|

105

|

111

|

First, I would thanks for this sharing this information. I have searched lot of websites, unfortunately i never find any blogs.

ReplyDeleteFinally, I found your blog. Here is the complete information what am looking for. Especially the information of shackles are very well explained.

Great Job.

Hello There. I found your blog using msn. This is a very well written article. I’ll make sure to bookmark it and return to read more of your useful information. Thanks for the post. I’ll certainly return.

ReplyDeleteliquid corrosion inhibitor

Thanks a lot for sharing this great post with us. I always find great knowledge from your site. Keep it up. We are thebest Lubricants Suppliers

ReplyDelete